or . . . The Shin Bone's Connected to the Thigh Bone

Getting to the root cause of problems can speed up the solutions. Even better - it can keep those problems from spring up somewhere else!

It’s Monday. You’ve poured your first cup of office coffee, you’re sitting at your desk with the steaming mug in your hands, ready to face the week. You open your email and . . .

The email bomb. Your boss, demanding to know why production has stalled on your main product line. AGAIN. You sit there and sweat as your coffee goes cold and your week begins to look bleak.

Nothing is more upsetting – to bosses or managers – than problems that repeat themselves. The first time a problem occurs, reasonable people are accepting about it. After all, sh*t happens. But when problems reoccur, patience runs out. And it should, because errors are costly and keep us from focusing on creating new value for the company.

Typically, when the same problem occurs over and over again, it’s for one of these reasons:

- The root cause was never identified, so each time we solve the problem we are actually only solving a symptom of the problem.

- The root cause was identified, but we failed to do the 2nd step of problem solving, which is error-proofing the process from that time forward.

Lean Manufacturing offers two excellent tools to avoid that Monday-morning, coffee-cooling, temper-raising situation. Root Cause Analysis, and Poka Yoke.

Root Cause Analysis

Root Cause Analysis (often called RCA in Lean) is one of the pillars of a quality system. A commitment to RCA can help a company quickly reduce errors and introduce more quality throughout its supply chain. There are four basic steps in RCA:

- Collecting all the information about the problem (which we will refer to as a non-conformance). Every little detail – even the details that seem inconsequential!

- Creating a visual map of the causal factors – the steps, missed steps, and errors that led to the non-conformance.

- Accurately identifying the root cause or causes (sometimes there is more than one factor at the root – but rarely more than three).

- Creating a solution that solves the root cause, and developing a corrective action plan.

Collecting the Information

5 Whys

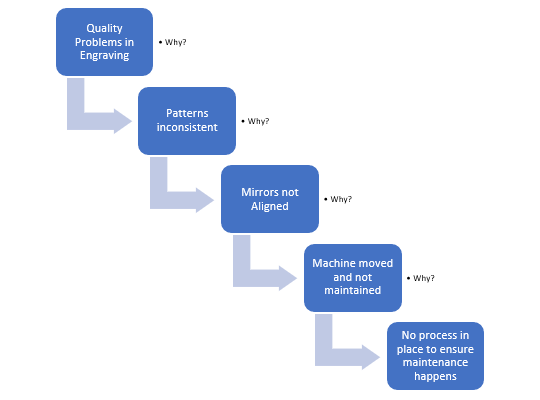

The simplest way to collect information about the causes of a problem is to ask questions. But these questions should be structured as a true interrogative technique – and not just a random set of questions. In fact, when you ask questions in this way, it can be diagrammed.

To do a 5-Whys approach (and the result may be achieved in 3 Whys, or 10 Whys – the approach is named 5 Whys because the theory is that most root causes can be uncovered in 5 or less), start with the most obvious problem.

- We are scrapping a lot of engravings due to poor quality. Why?

- The patterns are too deep in some areas and too shallow in other areas. Why?

- The mirrors are not in perfect alignment. Why?

- We did not do proactive maintenance when we moved the engraver to a new workspace. Why?

- Nobody thought of it, because there is no process in place to ensure machines are maintained after being moved.

Solution: Any time an engraving machine is moved, there must be a process in place to ensure that maintenance is done. Further discussion of the topic would probably led the group to decide that the machine merited regular preventive maintenance – perhaps quarterly.

How do you diagram this?

Why Do You Need Visual Maps?

Before we go on to the next RCA tool, let’s talk about visual maps. Visual maps are an important element of problem solving. When we represent information in a visual manner, we engage more of our brains in understanding the issue. Visual maps require us to structure information, which helps us to better comprehend, synthesize, and remember the information, which leads to generating more and better new ideas. In other words, making mental information visual helps our brains do a better job!

Fishbone Diagram

Another very useful RCA tool is called the Fishbone Diagram (trivia: This was originally called an Ishikawa Diagram). This is sometimes referred to as a Cause-and-Effect Diagram. The Fishbone is more useful than 5 Whys when you are dealing with more complex problems. As you will see, it can take into consideration many more variables than the 5 Whys approach.

When you first look at a Fishbone Diagram, it may seem complicated. But it’s actually very simple!

As with the 5 Whys, you begin by asking, “what is the problem?” Then, you diagram it like this:

The next step is to categorize the causes. For example, missing customer deadlines can involve a lot of different areas, including:

- Sales Process

- Production Process

- Purchasing Process

- Warehouse (pick/pack/ship) Process

Place these different cause categories on the Fishbone Diagram like this:

Obviously, we don’t have enough detail yet to solve the problem. So the next step is to brainstorm the contributors to the problem. This part of the Fishbone will likely look like this:

The team should continue to brainstorm the problems, until all the possible causes have been identified. Very complex problems may go to several levels of hierarchy. You can use different shapes and colors for the different levels to make the diagram easier to read.

Once the diagram is complete, it will be much easier for the group to identify all root causes and brainstorm solutions for them.

Conclusion

Getting to the root of problems is the only way to cure them. Consider the ramifications for your health. If you suddenly experience pain on the left side of your chest and numbness in your left arm, you don’t try to stretch it out or lay down and take a nap! You already know that these are signs of a heart attack, and you go straight to addressing the core issue (call 911!). You don’t spend time worrying about your sore arm. But what about medical emergencies you don’t already know about? The difference between a good medical outcome and a sad outcome is often based on getting to the right doctor who can quickly diagnose the core issue and treat it.

This is also important in business. Use these Lean tools to get to the root causes of problems. You’ll be solving another medical problem as well . . . the anxiety attacks that occur when you hear a dreaded problem has occurred again.

In next week’s Lean article we’ll discuss Poka Yoke, or how to make problems stay away.